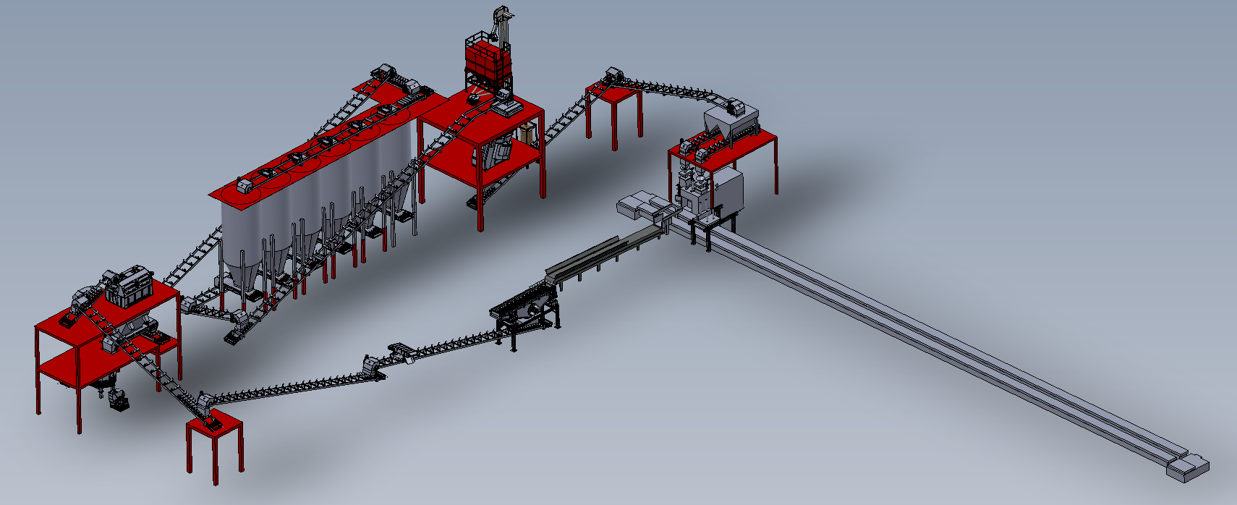

Cleaning Equipment

Shot blasting chamber for oversized castings weighing up to 100 kg;

Shot blasting machine type PG20X35 / 5TR-2829.

Casting dimensions: 2000 × 3500 mm, with a weight of up to 5000 kg.

Heat Treatment Section

Pit furnaces for general hardening: Ø 650 mm, depth 1600 mm; pit furnaces for general hardening Ø 800 mm, depth 2000 mm; hearth furnaces with a hearth size of 3500 × 1500 × 2200 mm; and a heat treatment furnace SDO 20.35.20 / 11 with a hearth size of 2500 × 2000 × 2000 mm.

The heating rate is from 10°C to 100°C per hour. The maximum temperature is 1130°C, and the maximum load weight is 6 tons.